-

SUSTAINABLE ENERGY SYTEMSMADE IN GERMANY

SUSTAINABLE ENERGY SYTEMSMADE IN GERMANY -

SUSTAINABLE ENERGY SYTEMSMADE IN GERMANY

SUSTAINABLE ENERGY SYTEMSMADE IN GERMANY

EC BIOHEAT

CO2-Negative Heating Solution

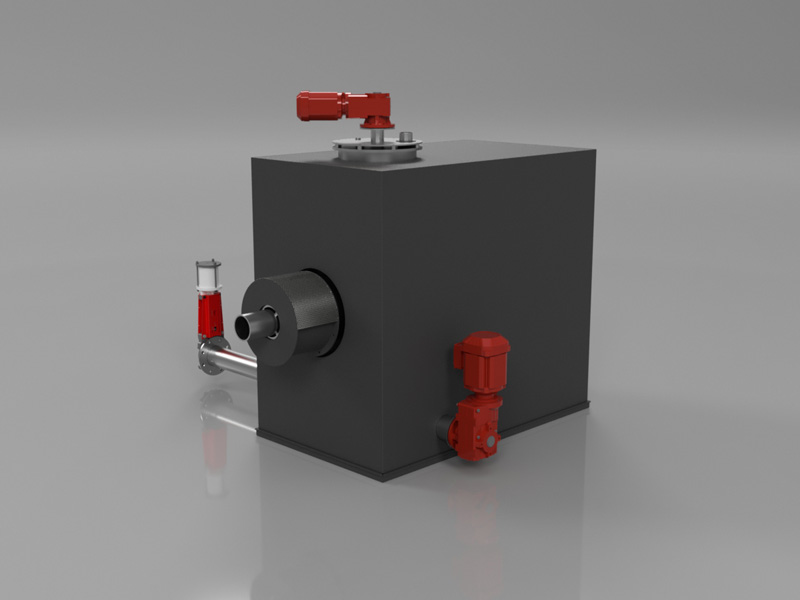

This system brings simplicity, durability and flexibility in a unique way compared to conventional pellet-based heating systems. We ensure top quality burning with minimal maintenance expenses and easy operation, thanks to a high temperature pyrolysis and separated gas flame. Low emission values without any filters, no matter what biogenic Fuel as long as it comes in 6mm Pellets. This means a decentralized exploitation of various residues or just a highly efficient CO2-negative wood-pellet burner suitable for any heat related application.

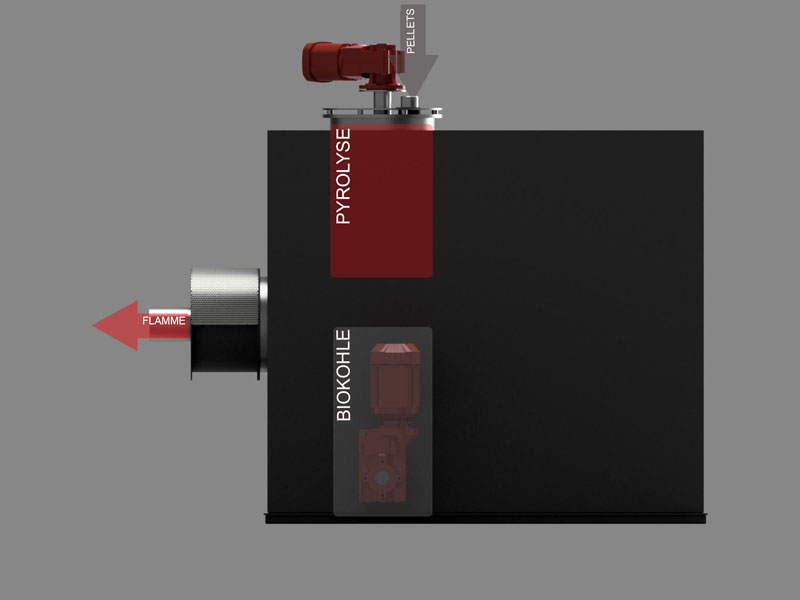

Process

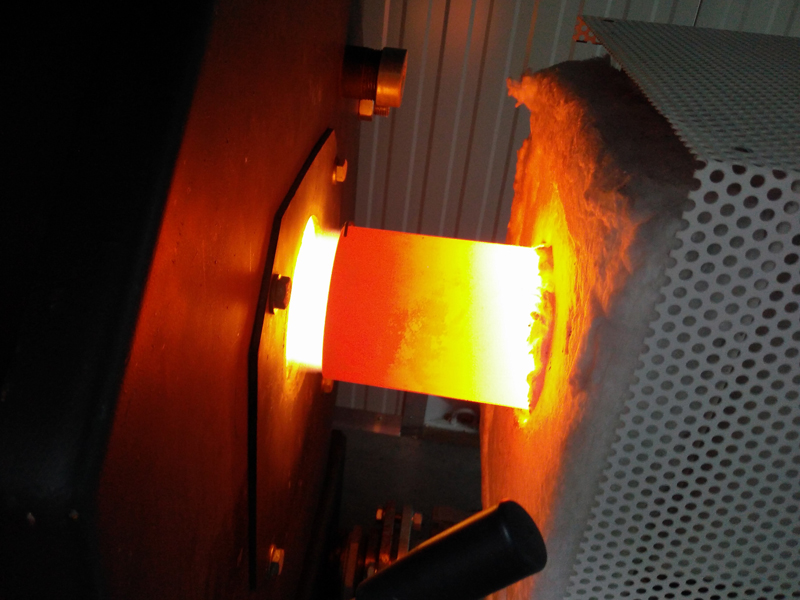

Pellets feed in to a burning chamber by a conventional crew conveyor. They ignite once and then will keep up the process themselves as new pellets feed in on top. To start the pyrolysis, the upper layers of pellets seals the burning pellets from air. A compressor creates a vacuum to suck the synthesis gas into a flame tube. The gas ignites due to the sudden presence of air inside the tube and creates a 1200°C flame. An air or water heat exchanger transfers the heat to its designated use.

A high quality biochar drops down from the burning chamber and feeds out by another screw conveyor. The process I fully automated and can be mobile accessed and controlled.

Parameter

Output: 180 kWp

Fuel: 6 mm pellets, wood or similar

Throughput: 1 t/d

Thermal Output: 160 kW

El. Consumption: 5 kWp

Biochar Output: 100 kg/d

Dimensions: 20’ Shipping Container

Installation

Depending on the needs, we can equip the unit with either an air or a water heat exchanger. This provides easy handling and integration and keeps additional costs low. Additionally it operates in its own borders to ensure a maximum of reliability and security. It comes in a standard 20-foot shipping container, already commissioned and ready to use after a few steps.

APPLICATION AREAS FOR EC BIOHEAT

-

Forestry

An ideal field of use for an EC BIOHEAT are locations with biogenic residues that can be recycled into fuel. The Forestry can rely on optimal resources like woodchips and leaves to deliver process heat or to heat up administration buildings.

-

Agriculture

Farmers can exploit all advantages since they have biogenic residues, need heat for various purposes and can use the biochar to improve their soil.

-

Fruits and Vegetables

Like in agriculture, fruits and vegetables benefit a lot from biochar and its enhancing properties. The heat can be used to heat greenhouses or administration buildings.

-

Viniculture

Especially in dry nutrient-poor regions, the EC BIOHEAT allows making a use out of green cut residues and enables the winegrower to improve and control its soil to an extent.

-

Horticulture

An optimal heating choice for smaller greenhouses and ecological horticulture.

-

Industry

A consistent, reliable and environmental friendly process heat or building heating. Optimal way to reduce carbon emission footprint.

-

Biogas

An environmental friendly commission-heating alternative or trace heating for plants with a high heat demand.

-

Municipal

The solution to isolated rural regions with biogenic residues. Optimal to heat up municipal buildings or private buildings in combination with a small distant heat distribution network.

-

Wellness

Environmental friendly heating for swimming pools, spa- or wellness-resorts with limited infrastructure connections.

BYPRODUCT BIOCHAR

10% of the fuel converts into high quality biochar that drops into a chamber beneath the burning chamber. A screw conveyor feeds the biochar out of the system. It contains out of over 90% carbon depending on the used fuel. Wood pellets for example convert into 96% carbon.

Thanks to the high temperature, we can produce a very clean product of way better quality than any similar system that produces biochar. Pollutant concentrations are well below the requirements of active carbon and with a specific surface of 200m2/g it is almost classified as such. That in combination with a water holding capacity of 150% makes it a perfect nutrition storage or filter.

APPLICATION EXAMPLES FOR BIOCHAR

-

Terra Preta

Already the indigenous people in the amazon delta or elsewhere aroud the globe knew about the positive effects of biochar in the soil. They still produce so called Terra Preta or Black Soil form biochar, feces, compost, potsherds and bones.

-

Agriculture

The positive effects of biochar were long forgotten, but recently some institutions and farmers try to prove its use again. Some already use its effects on soil and its property to seal odor from slurry in combination with effective microorganisms.

-

Special Crop

The biochar serves as a nutrition storage. It provides a constant level of irrigation due to its water holding capacity. We expect an up to 20% higher volume growth rate depending on the corresponding fertilizer.

-

Animal Feed

Biochar inside the feed can have positive effects on animal health. It improves the nutrient receptive, prevents diseases and reduces odor. In consequence the fertilising quality of slurry and dung rises.

-

Biogas

Studies say that biochar inside the digester improves gas yields up to 20% and bind ammonia to prevent ammonia inhibition. Some plants use it to filter sulphur.

-

Active Carbon

To classify the biochar as active carbon, you need to enlarge its specific surface to 300m2/g or higher.

-

Dye

In the textile or cosmetics industry, the biochar can be used as a dye thanks to its high carbon content.

Projects

Rotenburg

The system was built in cooperation with the Investitions- und Förderbank Niedersachsen (Nbank) and the network of technology, innovation and development (artie).

It was used to calculate and evaluate a series production and develop a final prototype. Since the heat is not usable at its current location, it is not in use.

Caiyu

The EC BIOHEAT was designed to compensate the loss of small coal ovens in rural areas, since China announced a total stop to coal as fuel in private households. It produced heat for several municipal buildings for demonstration purposes. Unfortunately, the project had to be stopped because the Chinese government announced to forbid all biogenic fuels as well. We are currently planning to build a new System for agricultural use.

Harbin

The EC BIOHEAT will be used as an environmental friendly commission-heating alternative and trace heating for a plant with a high heat demand.

We are currently at the planning stage.

Privacy Policy Notification

This site attempts to embed maps from the google web server. Please note that when loading google maps, personal information may be transmitted to google. Do you agree with the loading of google maps? You can find more information HEREContact

Energy CO2mpany GmbH & Co. KG

Tobagostraße 5

27356 Rotenburg (Wümme)

This email address is being protected from spambots. You need JavaScript enabled to view it.

Tel.: +49 4261 / 96346-0

Fax: +49 4261 / 67269-2

| Imprint | Privacy Policy |